In 2003, a healthcare worker infected with SARS went to a wedding in Hong Kong and checked into the Metropole Hotel. He fell ill the next day and went to hospital – but had already infected 16 other guests with rooms on the same floor, probably largely through their ventilation systems.

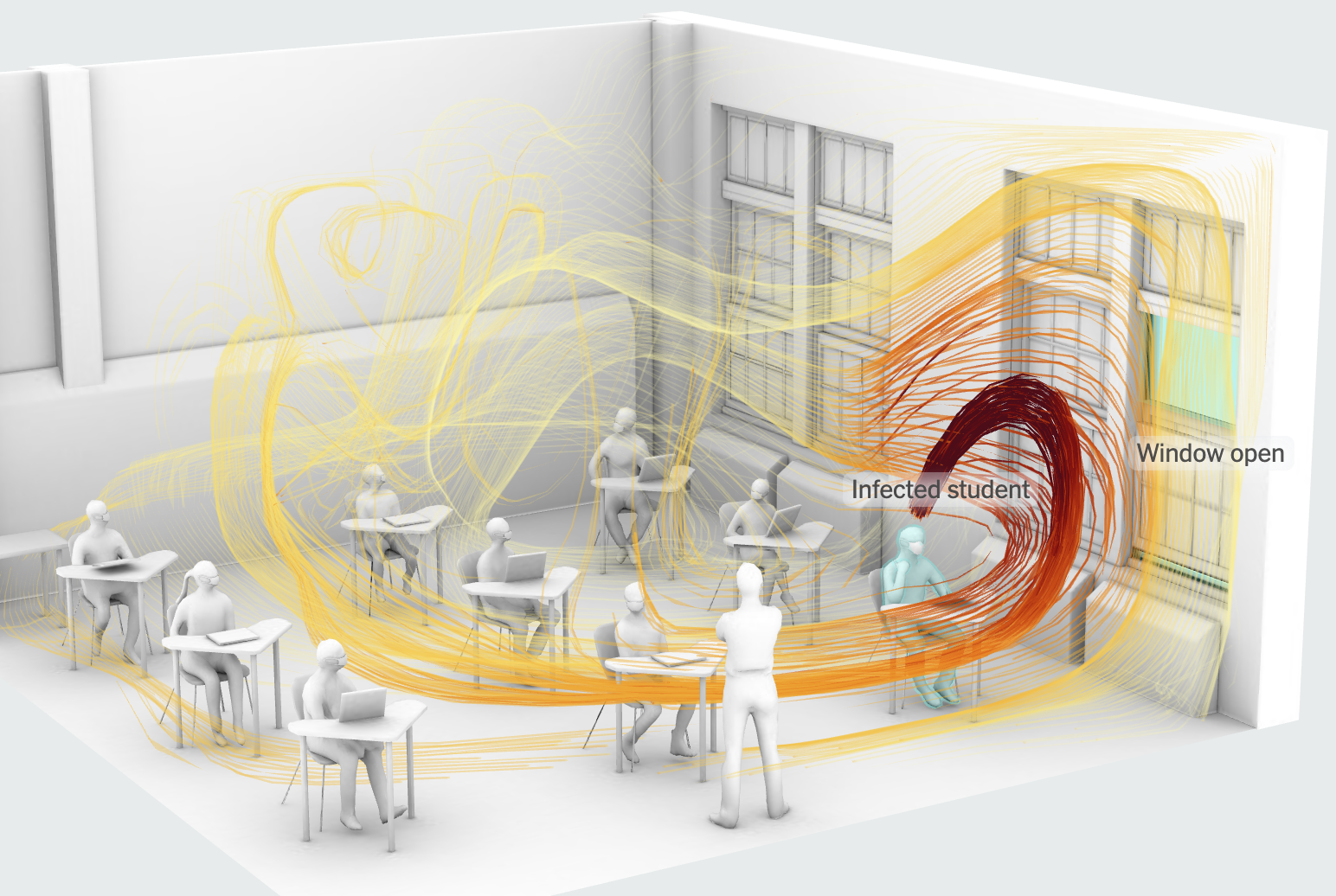

Move forward 17 years and managing ventilation is now a hot topic in reducing COVID risk. A person with COVID releases particles in droplets and aerosols whenever they speak, sneeze or cough. Droplets tend to fall to ground quickly, but finer sprays (aerosols) remain suspended in the air for long periods of time if the air is not removed from the room. Breathing in these aerosols puts other people in the room at high risk of developing a COVID infection, even once the infected person has left.

Fighting this means bringing in fresh air and removing stale air to quickly remove virus particles from the environment. It is an important piece of any plan to reduce COVID risks in a public building, along with keeping distance, hand hygiene and mask wearing, but it can be difficult to monitor how effective ventilation strategies are. CO2 monitoring can give reassurance that ventilation is working to help you get your building back to work safely.

How monitoring CO2 helps

CO2 levels provide a very useful signal for any facility manager trying to assess COVID risk and ventilation rates. Every person in a space breathes out CO2 at a constant rate, at a concentration around 40,000 parts per million (ppm) meaning it can give a good indication of aerosol load in the air, if someone in the room has COVID.

Over time this CO2 builds up in enclosed spaces, so that levels will exceed the natural background rate (around 400 ppm). An effective ventilation system will be able to expel stale air and bring in fresh at a rate that keeps the CO2 levels from building up to uncomfortable levels: and by diluting any infected air it will also reduce the risk of contagion to the people in the space.

Understanding CO2 levels across the whole building helps facilities managers identify what strategies are working, reduce high risk practises (such as holding meetings in unventilated spaces) and demonstrate to occupiers that the space is working for them in the fight against COVID.

What should CO2 levels be?

If you’re thinking about using CO2 to control COVID risks, it important to recognise that while absolute levels do matter, rate of change is important as well. A rapid build up of CO2 in a room is a clear sign of over occupation, and a slow reduction can be a sign of ineffective ventilation.

Background (atmospheric) CO2 levels vary slightly over time and location but are typically around 400 -420 ppm; in a mechanically ventilated buildings 800ppm – 1000ppm is a commonly used target for normal operation. Even before COVID, research shows levels above 1200 ppm have measurable impact on productivity and decision making (see CO2 and workplace productivity below).

The chances of catching COVID are affected by a range of factors as well as ventilation (including age, activity level and distance), and these effects are still being researched, so providing a single CO2 level as a target is misleading, but current consensus amongst authorities such as ASHRAE and the FEA suggests anything above 1000ppm should be avoided.

Prof Cath Noakes, expert in ventilation and infection transmission, goes a little further: “You should be looking for CO2 below 1000ppm, and ideally around 800ppm BUT there’s a bit more to it…to understand if the ventilation is adequate, you need to measure with the normal number of people in the space. If you measure with less people you will get a lower reading which could give a false impression that the ventilation is OK.”

What else can CO2 levels tell me?

As important as the absolute levels of CO2 is the rate of change. As Prof Noakes explains: “Transient effects also matter. The CO2 builds up and decays quickly when a room has a high airflow rate, but much more slowly in a poorly ventilated space. A single low reading doesn’t tell you the whole picture.”

Watching the rate of change gives a clear picture of which parts of the building are extracting waste air effectively. The graph below shows the decay of CO2 in a meeting room with good ventilation, vs ineffective ventilation.

Using decay curves like this it is possible to produce an estimation of air changes per hour and map these over the whole building to identify dead areas where ventilation is less effective. Sometimes there can also be ‘dead times’ – in one building monitored by Purrmetrix system last year meeting rooms that were effectively ventilated during operating hours were being used after working hours when ventilation systems were reduced. CO2 build up was rapid and dispersal very slow. The monitoring highlighted this risky behaviour which was discontinued.

CO2 and productivity

Improvements in ventilation have value beyond reducing COVID risk – many studies have demonstrated the link between high CO2 levels and reduced productivity in office workers. Most recently the Whole Life Performance study, from Oxford Brookes and LCMB, used Purrmetrix CO2 monitoring to demonstrate the relationship; finding subjects completed sample tasks 60% faster in environments with lower CO2 levels.

In schools, high CO2 levels also a cause for concern, and have been associated with declines in cognitive function scores in at least one Harvard study.

How do I put CO2 monitoring in place?

With all this in mind there are several key things to think about when designing a CO2 monitoring project:

How accurate are my CO2 sensors – how do they calibrate?

Before getting stuck on accuracy, it’s important to understand when it’s important and when it isn’t. Sensor manufacturers list accuracy as ± ppm ± a percentage of the reading – it’s common to find variation of 50 ppm and 3%, meaning at the lower limit of 400 a sensor can measure between 358 and 442 ppm. By sampling rapidly (up to 20 times a second) and taking an average they improve the accuracy of the read and produce a result close to the actual target. Accuracy measured this way will improve at higher CO2 levels (measuring 1000ppm the same error could produce a result of 920 – 1080 ppm, before averaging) and it has little effect on rate of change measurements.

As important as accuracy for long term monitoring is how the devices are calibrated. Low cost devices can drift in performance over time, and manual recalibration is very labour intensive. The best solutions have sensors that can self calibrate and reset back to a base level of background CO2 on a regular cycle.

How easy is it to deploy and maintain the sensors.

Sensors need to be robust, easy to fit, and – if you are working with a large site – easy to identify. Once fitted, the best can be left with no further visits for calibration or battery replacement.

Where am I putting the CO2 sensors?

This is important as you want to get the most representative figure for a gas that will vary across the space. Measurements should be taken from every room where people regularly gather and ideally from the same number of points across an open plan office as points where the air is extracted. The best locations are fairly central, not too low (CO2 sinks so this will raise your result), not directly in front of a person or a vent. We favour underside of desks or meeting rooms, if power leads will extend to those locations.

How much data do I get? How do I make sense of it?

For professional ventilation management, transient effects matter, meaning it is important to be able to see data over long periods of time, and ideally understand quickly which area this data relates to. On a large site all this data must be quickly turned into actionable information, such as heatmaps, alerts and ventilation measurement.

As facilities managers plan for re-opening sites, ventilation provides an effective way to reduce COVID risk and CO2 monitoring is an important tool in managing ventilation strategies. With hundreds of CO2 sensors monitoring thousands of hours of CO2 data, the Purrmetrix solution is a proven and powerful system for measuring and analysing ventilation rates. If you are working on ventilation strategies in your estate and have questions, get in touch and we can help.